Stanford's Breakthrough Reactor in Cutting Industrial CO2

A New Electric Reactor Promises to Slash Carbon Emissions in High-Temperature Manufacturing Processes

Table of Contents

- The Industrial Carbon Emissions Problem

- Stanford’s Groundbreaking Reactor

- Why Industrial Emissions are a Problem

- Reactor Efficiency & Proof-of-Concept

- Future Potential

↓ Member Exclusive Content, Sign Up for FREE to Access ↓

Stanford University researchers have made an exciting breakthrough in the push to reduce industrial carbon emissions. They’ve developed a new thermochemical reactor powered by electricity, which could drastically lower carbon dioxide (CO2) emissions from industries that currently contribute about 30% of the U.S.'s total carbon output. To put that in perspective, these industries emit more CO2 than all the cars, trucks, and airplanes in the country combined.

How the Technology Works

The reactor, designed by a team led by Jonathan Fan, Associate Professor of Electrical Engineering at Stanford, uses magnetic induction—similar to what’s used in induction stoves—to generate heat. This technology is incredibly efficient, converting over 85% of the electricity it uses directly into heat.

Why Industrial Emissions are a Problem

Industries like steel, cement, and chemical production are major sources of CO2 emissions. Cutting these emissions is crucial in the fight against climate change. The challenge is that many of these processes require extremely high temperatures, often over 1,500 degrees Celsius (2,732 degrees Fahrenheit). Traditionally, this heat has been produced by burning fossil fuels, leading to significant CO2 emissions.

The Challenge of High Temperatures

Achieving these high temperatures without producing CO2 has been a major hurdle. Existing technologies either struggle to reach these temperatures or are too expensive. This is where Stanford’s electric reactor stands out. It can reach the necessary temperatures using electricity, which can be sourced from renewable energy, making it a much cleaner option.

A Game-Changing Technology

Think of it like replacing an old, inefficient gas furnace with a modern electric heater. The new system does the same job but is cleaner and more efficient. On a larger scale, this reactor could lead to significant reductions in CO2 emissions from industrial processes, making it a game-changer in the fight against climate change.

Published Aug. 19 in Joule.

Understanding the Impact

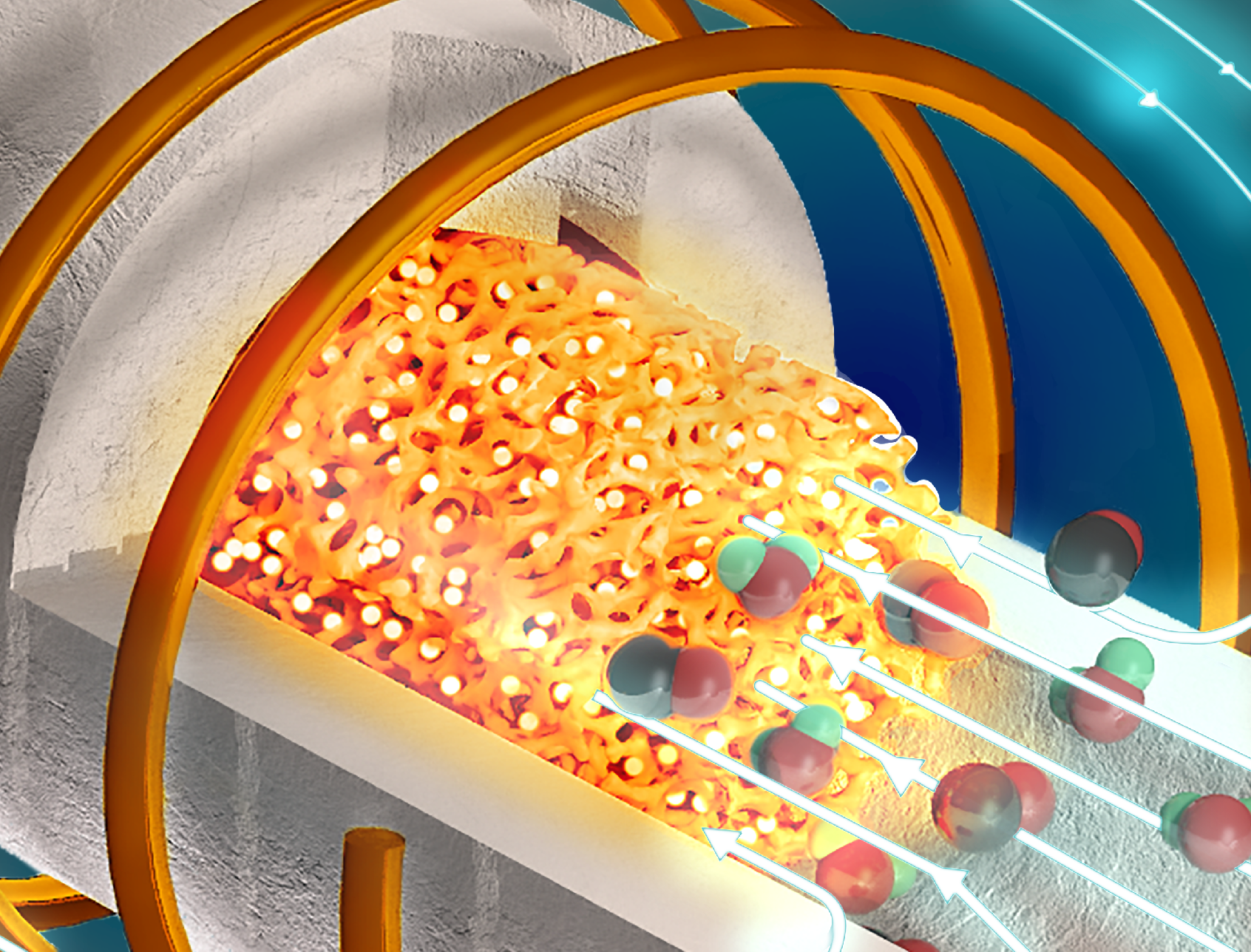

The reactor’s core features a 3D ceramic lattice that generates heat evenly and quickly across a large surface area. This design is key to its high efficiency and makes it possible to drive chemical reactions effectively. In tests, the reactor demonstrated 85% efficiency and successfully converted CO2 into carbon monoxide and water—a process that can be used to create sustainable fuels.

The reactor is not only more efficient but also more compact and cost-effective than traditional fossil fuel-based reactors. It simplifies infrastructure by eliminating the need for extensive piping and external heat transfer systems, which also reduces energy losses. Jonathan Fan points out that as these reactors are scaled up or operated at higher temperatures, their efficiency could increase even further. This shows the promise of electrification—not just replacing current technologies but improving upon them.

Why This Matters

If adopted widely, this technology could play a major role in reducing industrial carbon emissions. It offers industries a way to continue their high-temperature processes while significantly cutting their carbon footprint—a huge step toward a more sustainable future.

Fan and his colleagues, including Juan Rivas-Davila, Associate Professor of Electrical Engineering, and Matthew Kanan, Professor of Chemistry, are now working on scaling up this technology. They’re exploring its use in carbon capture processes and cement manufacturing, both crucial areas for reducing industrial emissions. The team is also collaborating with partners in the oil and gas sectors to adapt the technology to their needs, aiming for widespread adoption.

As industries face increasing pressure to reduce their emissions, this innovation from Stanford could be a key tool in the transition to a more sustainable future. The potential for this technology to cut emissions while boosting efficiency highlights the critical role electrification can play in industrial decarbonization.